sheet hlau laser txiav tshuab

cov khoom paub meej

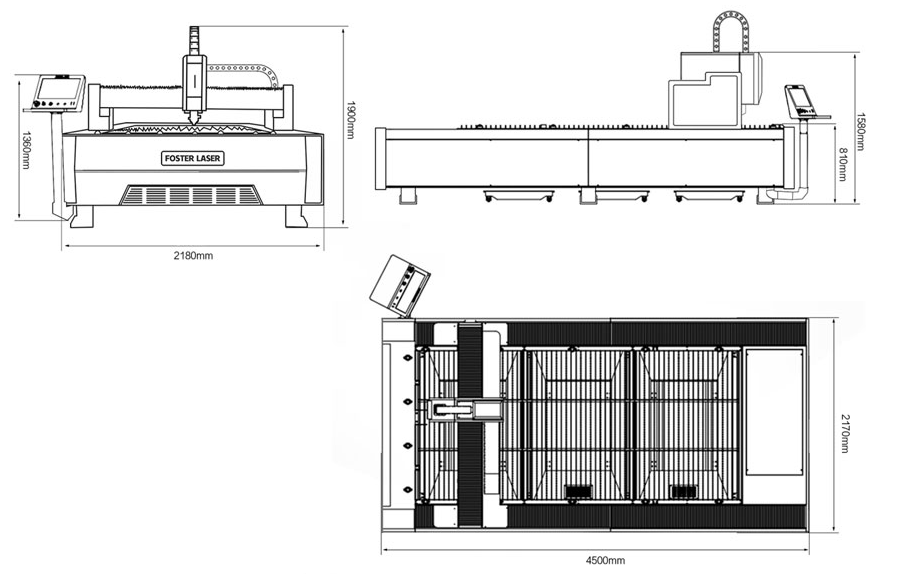

| Qauv | FST-FM 3015Fiber Laser Tej Tshuab |

| Ua Haujlwm Loj | 1500 * 3000 hli |

| Laser zog | 1/1.5/2/3/4/6/8/12KW TSI |

| Laser wavelength | 10 80nm |

| Laser Beam zoo | <0.373 mr |

| Lub neej ua haujlwm ntawm Fiber Source | Ntau tshaj 10,0000 teev |

| Hom hauj lwm | Liab Dot Pointer |

| Txiav Thickness | 0.5-10mm Tsis pub dhau qhov ntau yam Standard Precision |

| Max. Idle khiav ceev | 80-110M / min |

| Max acceleration | 1 G |

| Reorientation raug | Nyob rau hauv +0.01mm |

| Lubrication System | Hluav taws xob Motored |

| Txias hom | Dej txias thiab kev tiv thaiv system |

| Tshuab fais fab | 9.3KW/13KW/18.2KW/22.9KW TSI |

| Pab Gas rau Txiav | Oxygen, Nitrogen, Compressed Cua |

| Tau tshaj Software | AutoCAD, CorelDraw, thiab lwm yam. |

| Kov Tswj | Wireless Control kov |

| Graphic Format | DXF/PLT/AI/LXD/GBX/GBX/NC code |

| Fais fab mov Voltage | 220V1Ph lossis 380V3Ph, 50/60Hz |

| Warranty | 2 Xyoo |

| Qauv | FST-FM Series |

| Tswj System | CypOne/CypCut - phooj ywg |

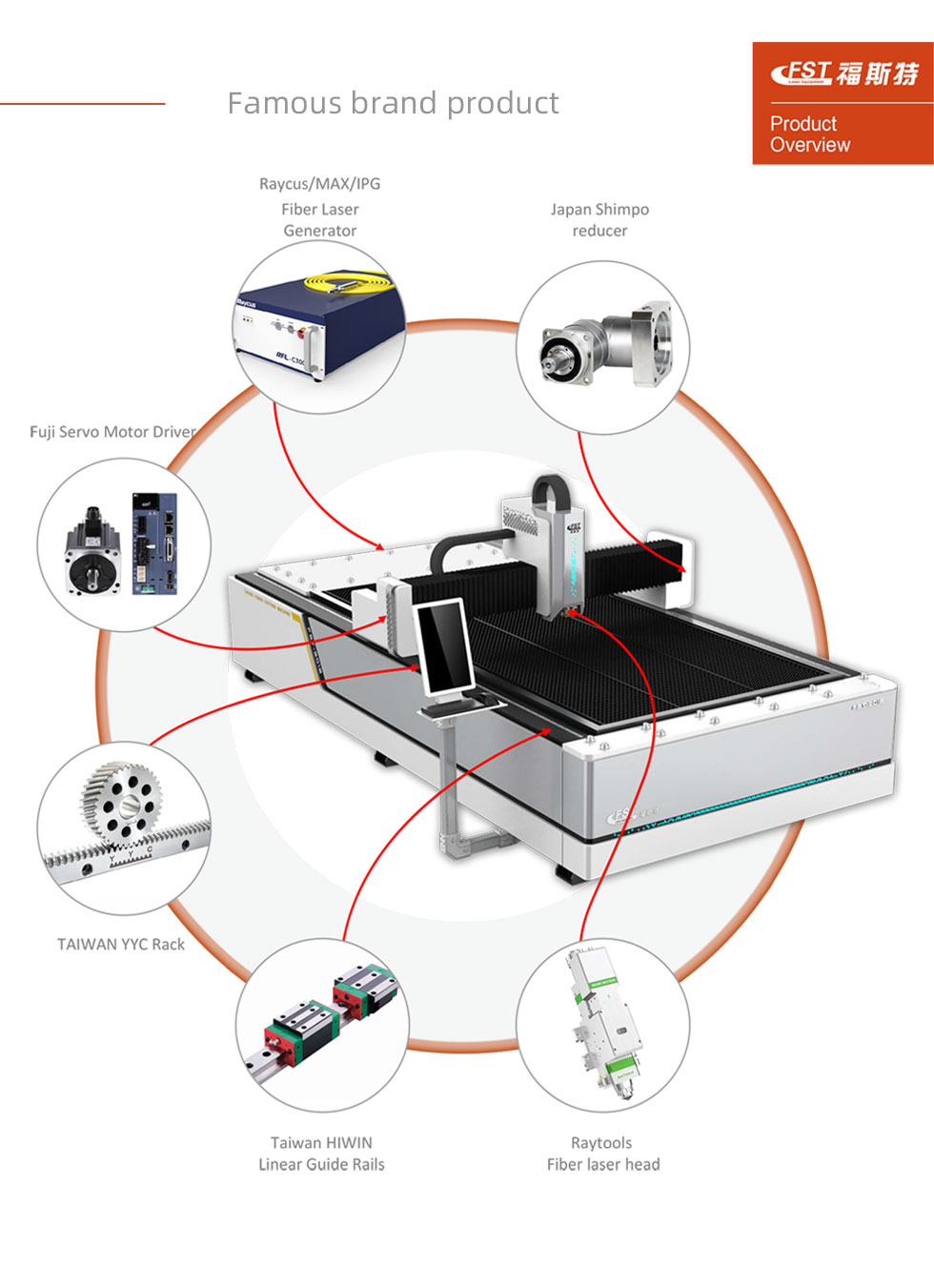

| Tsav thiab Motors | Nyiv Fuji Servo Tsav System |

| Fiber Laser Lub Taub Hau | Raytools Laser Lub Taub Hau |

| Fiber Source | Raycus lossis Max lossis IPG |

| Lubrication Svstem | Hluav taws xob Motored |

| Qhia Rails | Taiwan HIWIN Rails |

| Khib thiab iav | Taiwan YYC khib |

| Tsav system zog | X = 0.75/1.3KW, Y = 0.75/1.3KW, Z = 400W |

| Reducer | Nyiv SHIMPO |

| Electron Cheebtsam | DELIXI hluav taws xob |

| Chiller | HanLi/S&A |

| Qhov hluav taws xob | 220V 1Ph lossis 380V 3Ph, 50/60Hz |

| Qhov hnyav tag nrho | 1.9t ib |

| Qauv | Paub meej |

| Tswj System | CypCut |

| Tsav thiab Motors | Yaskawa Servo Tsav System |

| Fiber Laser Lub Taub Hau | RAYTOOLS BM110 Tsis Siv Neeg Pom Zoo Laser Lub Taub Hau |

| Stabilizer | Ua hauv Suav teb |

| Exhaust kiv cua | 3 KW |

| Wododen ntim | Nrog hlau bracket |

Cov khoom lag luam nto moo

Cast Aluminium Beam

Monolithic cam khwb cia aluminium beam

Tsis muaj deformation, lub teeb yuag, siab zog Lub teeb hla kab tso cai rau cov cuab yeej ua haujlwm ntawm tus nqi nrawm dua, txhawb kev ua haujlwm zoo thiab zoo.

Lub teeb crossbeam tso cai rau lub tshuab txav ntawm tus nqi nrawm dua thiab txhim khu kev txiav.

Kev lag luam aerospace aluminium profile beam xyuas kom meej tias cov cuab yeej muaj kev ua haujlwm zoo, ua rau muaj kev ua haujlwm zoo thaum tswj xyuas kev ua haujlwm zoo.

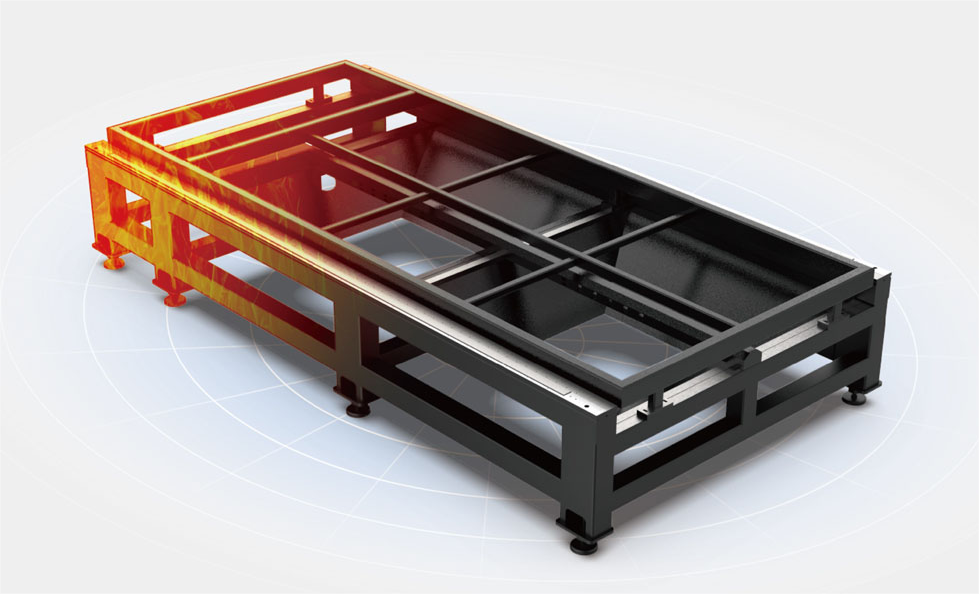

Muaj tshuab txaj

Lub txaj lub intemal qauv yog ib tug aviation metahoneycomb qauv welded ua ke nrog ib tug xov tooj ntawm rectanqular hlab. Stiffeners yog qhov chaw (hauv cov hlab rau strenathen lub txaj lub strenathand tensile lub zog, nrog rau qhov tsis kam thiab ruaj khov ntawm quide rail, tiv thaiv deformation

Nws paub tseeb tias lub tshuab yuav ua kom raug rau lub sijhawm ntev thiab yuav tsis cuam tshuam rau nws lub neej.

Lub zog tensile siab, ruaj khov, thiab lub zog, tso cai rau 20 xyoo ntawm kev siv yam tsis muaj kev cuam tshuam

Friendess Control System CypOne / CypCut

CypCut daim ntawv txiav software yog anin-depth tsim rau fiber ntau laser cuttingindustry.It simplifies complex CNCmachine lag luam thiab integratesCAD.Nestand CAM modules nyob rau hauv oneFrom drawing, nesting rau workpiececutting tag nrho yuav ua tiav los ntawm ob peb clicks.

1.Auto OptimizeImported Drawing

2.Graphical Cutting Technique Setting

3 Yooj Yim Ntau Lawm Hom

4.Statistic ntawm ntau lawm

5 Precise Ntug Nrhiav

6.Dual-Drive yuam kev Offset

Laser Txiav Lub Taub Hau

Kev Tiv Thaiv Ntau

3 tiv thaiv lo ntsiab muag, zoo heev collimatingfocus lens tiv thaiv. 2-txoj kev kho qhov muag watercooling ncua sijhawm ua haujlwm tsis tu ncua.

High-precision

Txhawm rau kom tsis txhob poob qis, siv lub tshuab kaw-loopstepping. Repetition accuracyis 1 M thiab qhov ceev ceev yog 100 mm / sDust-proof rau lP65, nrog patent-protectedmirror cover phaj thiab tsis muaj lub kaum sab xis tuag.

Ntau Hom Lub Taub Hau Laser Muaj

Peb tuaj yeem muab tag nrho cov zoo laser taub hau. Nws tau raug sim los ntawm peb tau ntev